Play Text-to-Speech:

Motor vibration is an inherent characteristic of any rotating equipment. While a certain amount of vibration is normal, excessive vibration can lead to serious problems, including damage to the motor itself, increased noise, reduced efficiency, and even safety hazards. Therefore, it’s crucial to understand the causes of motor vibration and implement effective solutions to minimize its impact.

Causes of Motor Vibration:

- Unbalanced rotor: This is the most common cause of vibration in motors. An unbalanced rotor can be caused by uneven weight distribution, loose components, or misalignment.

- Bearing wear: Worn bearings allow the rotor to move around excessively, causing vibration.

- Misalignment: Misalignment of shafts or pulleys can create uneven forces that lead to vibration.

- Looseness: Loose parts within the motor, such as bolts or connections, can vibrate as they move.

- Electrical problems: Faulty windings or loose electrical connections can cause electrical imbalances that manifest as vibration.

- Excessive load: Operating a motor beyond its rated capacity can put excessive strain on the components, leading to vibration.

Effects of Excessive Motor Vibration:

- Motor damage: Vibration can stress and wear down motor components, leading to premature failure.

- Increased noise: Excessive vibration can generate loud noise, creating discomfort and potentially violating noise regulations.

- Reduced efficiency: Vibration can cause friction and energy losses, reducing the motor’s overall efficiency.

- Safety hazards: In extreme cases, severe vibration can cause parts to loosen or break, creating potential safety hazards.

Solutions to Reduce Motor Vibration:

- Balancing the rotor: Balancing ensures the rotor rotates evenly, eliminating vibration caused by uneven weight distribution.

- Tightening loose parts: Securing all loose components within the motor reduces vibration from unnecessary movement.

- Aligning shafts and pulleys: Proper alignment ensures smooth rotation and prevents vibration caused by misalignment forces.

- Replacing worn bearings: Worn bearings should be replaced to eliminate excessive rotor movement and reduce vibration.

- Fixing electrical problems: Addressing faulty windings or loose connections ensures proper electrical operation and eliminates vibration caused by electrical imbalances.

- Reducing the load: Operating the motor within its rated capacity reduces stress on the components and minimizes vibration.

- Using vibration dampers: These specialized devices absorb vibration, reducing its overall impact.

- Mounting the motor on vibration isolation pads: These pads decouple the motor from its mounting surface, effectively isolating vibration and reducing noise transmission.

- Implementing a variable speed drive: This allows controlling the motor speed, potentially finding a speed range with lower vibration levels.

- Regular inspections and maintenance: Regularly inspecting and maintaining the motor helps identify and address potential issues before they cause excessive vibration.

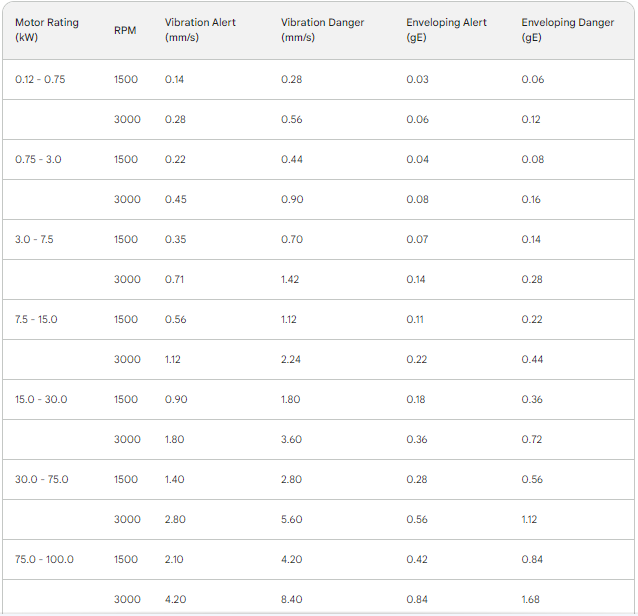

Table of Motor Vibration Alert and Danger Levels:

Note:

- These values are general guidelines and may vary depending on the specific motor, operating conditions, and other factors.

- Enveloping values are calculated from the vibration signal using specific algorithms.

- Always consult the manufacturer’s specifications and recommendations for your specific motor.

Sources:

- ISO 10816-3: Mechanical vibration – Evaluation of machine vibration by measurements on bearings

- ANSI/VMA 201-2019: Vibration and noise control for electric motors and generators

- ABB Technical Paper 2VBB000012: Vibration Monitoring and Fault Diagnosis for Electric Motors

Additional Tips:

- Keep accurate records of vibration readings over time to identify trends and potential problems early.

- Invest in reliable vibration monitoring equipment to track vibration levels continuously.

- Consult with a qualified technician if you suspect excessive vibration or are unsure about the cause.

By understanding the causes and effects of motor vibration, and by implementing effective solutions, you can minimize its impact and ensure the smooth and efficient operation of your motors. Remember, early detection and prompt action are key to preventing costly repairs and downtime.

Maintenance, projects, and engineering professionals with more than 15 years experience working on power plants, oil and gas drilling, renewable energy, manufacturing, and chemical process plants industries.